Marking on electric car batteries

Electric cars are a growing transportation option, especially thanks to people’s awareness of the environment.

That is why we want to focus on one of the most important parts for them: batteries and, more specifically, on the marking of electric car batteries.

Coding of lithium batteries

There are a multitude of marking options on all parts and elements that make up any final product. All markings are regulated in order to ensure correct coding and traceability of car batteries (also applicable for lithium batteries for scooters and electric bicycles).

The marking codes will depend largely on the type of battery and the country of manufacture. In addition, as there are a large number of batteries, these markings must also specify the purpose of each battery and all its characteristics.

Generally, the marking should specify the following information:

- Manufacturer’s name and country.

- Battery capacity.

- Rated voltage, cold start current.

- Battery Type.

- Date and year of issue.

- The number of cells in the battery box.

- Contact polarity.

- Alphanumeric characters showing parameters such as load or maintenance.

- Etc.

In addition, other battery components where we will need code marking will be:

- Battery cell: Datamatrix/QR laser code on the top of the part.

- Electric battery pack: Datamatrix/QR laser code on the side of the part.

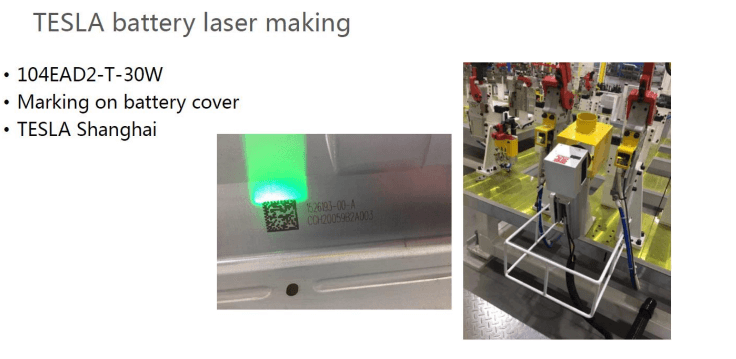

- Battery module: Datamatrix/QR laser code on the cover.

Examples:

Thanks to all these parameters, the mechanics, manufacturers and distributors of these elements will know exactly how to store and guarantee the quality of the batteries and motors that will allow the final product to be satisfactory.

Here are some of the most efficient systems to perform industrial marking or engraving of car batteries:

Etching systems in electric car batteries

At Sivart we have a wide variety of industrial marking systems that will allow you to achieve the best results. We have from portable marking machines to integrated marking machines to incorporate in an industrial line as the integrated marking machines. Both options allow an optimal marking on electric car batteries (or any other part of the vehicle).

All SIC Marking markers, of which Sivart is the official supplier in Spain, come with set-up and installation service, as well as training for your company and employees. It is also important to add that speed, proximity and efficiency in after-sales service is another of our added values.

If you need to find the perfect solution for your company or you simply have doubts, contact us without obligation and we will be happy to advise you as soon as possible.

Characteristics of electric vehicles

The new vehicles with more sustainable and eco technology are known by the following acronyms. All marking systems are compatible with the following vehicles and even for other parts such as bodywork, glass, metal parts, etc.

The acronym NEVs = New Engine Vehicles, especially electric vehicles, is used to distinguish traditional gasoline vehicles. Cars with the acronym NEVs are as follows:

- Plug-in hybrid electric vehicles (PHEVs)

- Battery electric vehicles (BEVs), also known as pure electric vehicles (EVs).

- Fuel Cell Electric Vehicles – Hydrogen (FCEVs)

Characteristics of NEVs:

- No noise pollution

- No emissions / pollution

- Simple structures, fewer parts/pieces = simple maintenance

- Energy saving, recycling and reuse

At Sivart, we have experience in the automotive sector and in the marking of all types of vehicle parts and materials. Contact us without obligation and our team will help you find the best solution for your project.