Innovation in industrial marking: texturization and laser surface treatment

At SIC Marking, we have always been at the forefront of industrial marking technology, providing advanced solutions that not only meet the needs of our customers, but also promote sustainability and efficiency in their production processes.

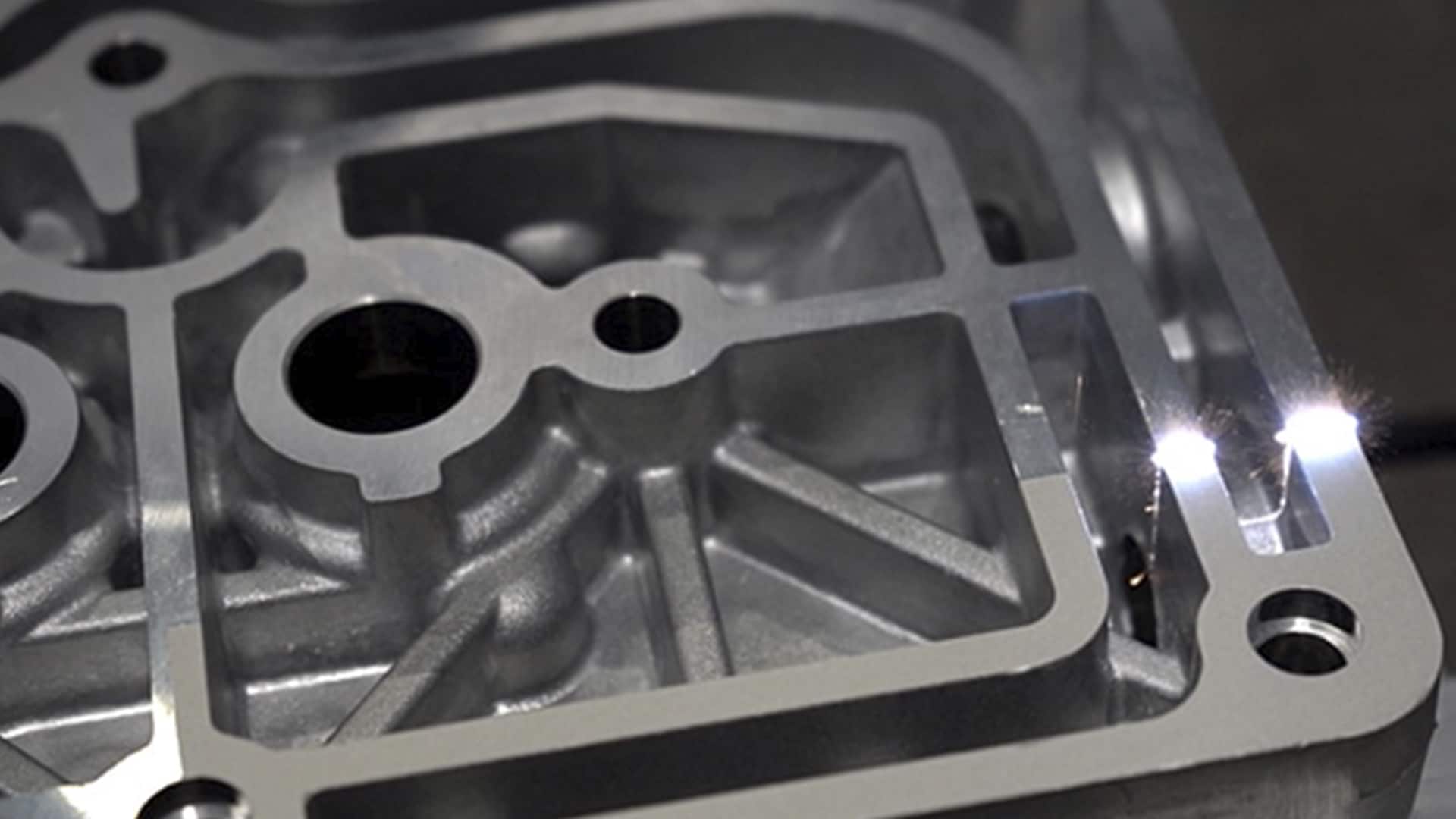

Today, we are introducing an evolution in our capabilities: the use of our marking laser for texturing and surface treatment.

A new horizon in laser marking

Traditionally, laser marking has been an invaluable tool for component identification and traceability in a variety of industries. However, our commitment to innovation has led us to explore and expand the applications of this technology.

Now, not only can we mark, but we can also texture and treat surfaces with the same laser equipment. This breakthrough opens up a number of new possibilities for improving the quality and functionality of industrial products.

What is laser texturing?

Laser texturing is a process that uses lasers to modify the surface of a material in a controlled and precise manner. It can be thought of as a process in which a high-intensity laser beam is used to create micro- and nanostructures on the surface of a material. These structures can vary in shape, size and pattern, allowing unprecedented customization of the surface properties of materials.

Texturing and surface treatment applications

The ability to texture and treat surfaces with lasers has significant implications in a variety of industrial sectors. Below, we explore some of the most promising applications:

- Improved adhesion

In industries such as automotive and aerospace, adhesion of composite materials and coatings is crucial. Laser texturing can create specific patterns on surfaces that significantly improve the adhesion of paints, coatings and other materials. This not only improves the quality of the final product, but also reduces the risk of failure.

- Friction reduction

In mechanical components, friction can be a serious problem affecting performance and durability. By creating microstructures on surfaces, laser texturing can reduce friction and wear, extending component life and improving operational efficiency.

- Aesthetic and functional properties

The ability to texture surfaces also has applications in aesthetic product design. From electronic devices to jewelry, creating unique patterns and textures can differentiate products in a competitive marketplace. In addition, these treatments can impart functional properties such as slip resistance, improved tactile feel, etc.

Sustainable advantages of laser texturing

Sustainability remains a fundamental pillar of our operations at SIC Marking. Incorporating laser texturing into our solutions not only expands our customers’ capabilities, but also promotes more sustainable practices:

- Waste reduction

As with traditional laser traditional laser markinglaser texturing and surface treatment operate without physical contact with the material. This eliminates the need for additional consumables such as abrasives or chemicals, significantly reducing waste generation and the environmental footprint of production processes.

- Lower energy consumption

The efficiency of laser surface treatment allows for faster and more precise operations, resulting in lower energy consumption compared to traditional texturing and finishing methods. These energy savings contribute directly to a more sustainable and cost-effective operation.

- Improved durability

Laser surface treatments often result in increased durability and resistance to environmental and mechanical factors. This reduces the need for maintenance and component replacement, reducing the consumption of materials and resources throughout the product life cycle.

It is important to engage in the development of technologies that not only improve the efficiency and quality of industrial production, but also promote sustainability and care for the environment. The ability to texture and treat surfaces with our laser equipment represents a significant advance in this direction.

We invite all our customers to explore the possibilities that this new application can offer. If you have any questions or would like to learn more about how laser texturing can benefit your operation, please do not hesitate to contact us.

At SIC Marking, we are here to help you reach new levels of innovation and sustainability in your business. For more information about our laser marking and texturing solutions, please contact us.