Industrial Marking of Aircraft Parts

Have you ever thought about how aircraft parts are industrially marked to ensure traceability and safety? In the following article, we will explore the importance of laser marking in the aviation industry, focusing on key parts such as turbine blades, landing gear and brake discs. Previously, we have talked about traceability in the aerospace industry and laser cleaning.

Industrial Marking on Turbine Blades

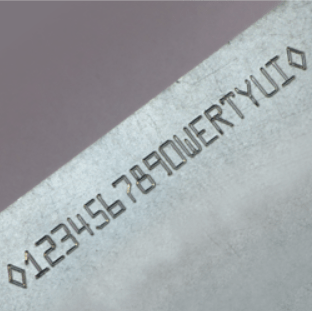

We start with one of the indispensable elements of an aircraft, the turbine blades. Industrial marking plays a very important role in the identification and traceability of these elements. Thanks to the use of laser technology, we can mark specific and vital information on turbine blades, such as serial numbers, lot codes or manufacturing dates. This facilitates the necessary tracking throughout the entire life cycle of the blades, facilitating their maintenance, inspection and replacement when required.

Industrial Marking on the Landing Gear

Of course, aircraft have a large number of components, and the landing gear is another essential component of an aircraft. Industrial marking plays an important role in their identification and traceability, and thanks to laser technology, information such as part numbers, manufacturing data and other relevant details can be marked on landing gear parts. Efficient parts management guarantees proper maintenance and ensures optimum performance during landings and takeoffs.

Industrial Marking on Brake Discs

Apart from the landing gear and turbine blades, brake discs are another of the elements we will focus on in this article. Brake discs are crucial for safety in the aeronautical industry, and industrial marking is essential to guarantee the traceability and quality of these components. With the use of laser technology, we can mark information such as technical specifications, serial numbers, and manufacturing dates on brake discs. This allows precise tracking of the discs throughout their service life, facilitates maintenance interventions, inspection and replacement in case of wear or damage.

Benefits of Laser Marking in the Aerospace Industry

As we have seen in the previous paragraphs, laser marking on aircraft parts offers many key benefits. On the one hand, it ensures traceability and accurate identification of components, which is essential for aircraft safety and maintenance. On the other hand, industrial marking facilitates the efficient management of parts by providing clear and legible information on their characteristics, origin or manufacturing dates.

Another of the most important benefits of industrial marking, and one that we have repeated throughout the article, is its great durability and resistance. Laser marking on aircraft parts are permanent and do not fade with the passage of time or weather conditions, ensuring legibility even in extreme conditions. In addition, the speed and accuracy facilitates industrial marking, enabling efficient production and reducing downtime in the aircraft manufacturing and maintenance process.

Importance of Laser Marking on Aircraft Parts

The industrial marking of aircraft parts is essential and indispensable in the aeronautical industry for several reasons. On the one hand, it ensures traceability and identification of each part. This is essential for the safety and maintenance of aircraft, as it facilitates precise tracking of parts from the time they leave the factory to the time they are installed, and later, their maintenance.

On the other hand, industrial marking allows us to manage more efficiently the different parts. Thanks to the clear and legible information marked on each of the components, the different technicians can quickly identify the correct parts during maintenance, replacement…. Marking, therefore, allows us to save time and reduce aircraft downtime, ensuring a safer and smoother operation.

Other aspects to highlight are the durability and resistance of the marking in the aeronautical industry. Thanks to its high legibility and permanence, even under extreme conditions such as high temperatures, vibrations and exposure to chemical products, the marking guarantees that the essential information on the parts, such as serial numbers, comply with all quality and safety standards in the long term.

Marking also helps to detect counterfeit parts and prevent other frauds, avoiding the substitution or manipulation of important components, thus ensuring the safety and integrity of the aircraft.

Sivart/SIC Marking Solutions in the Aeronautical Sector

Ultimately, through laser technology, precise and durable identification of components such as turbine blades, landing gear and brake discs is achieved. This contributes to efficient management, proper maintenance and optimum aircraft performance.

At Sivart/SICMarking, we have many years of international experience in the industrial marking market in all kinds of laser, micro-percussion or scratch technology. To solve any doubt about our equipment, and if you wish to obtain more information about industrial marking in the aeronautical industry, do not hesitate to contact us.