Industrial green laser marking

Today at Sivart we want to introduce you to a new type of laser marking, different from the fiber marking we have always sold. This is an option that opens new doors in the world of marking and we are sure that many of you will be interested in it. Let’s go for it!

What is green laser marking

Green laser marking machines are designed for cold and complex marking on materials that do not react to other wavelengths. Thanks to the diameter of the laser beam, the results offered by this laser technology are of unsurpassed quality and marking precision.

The green laser is the best choice if you want to perform permanent marking on highly reflective materials and sensitive plastics.

Advantages of cold laser marking

The green laser marking, also known as cold laser, is the one that performs the marking with minimal thermal stress. This type of marking concentrates the laser beam directly and permanently without altering the material, i.e. it does not generate heat, thus avoiding burns or deformation. As mentioned above, it is the perfect solution for marking sensitive and soft materials and components.

The green laser markers we offer at Sivart guarantee small and fine marks with exceptional resolution.

Another distinguishing feature is its great versatility. Thanks to the range it uses (a wavelength of 532 nm), it can mark materials that in many cases would not react to infrared wavelengths. In the following section, we list some of the materials that the marker is capable of marking.

Green laser engraving applications

As mentioned above, green laser engraving has a multitude of applications on a wide variety of materials:

- Plastic engraving

- Some ceramics

- Copper, gold, silver

- Reduced heat transfer

- Crystal / Glass

- Thinner markings (smaller beam diameter)

- Automotive marking

- Engraving on leather or imitations

- …

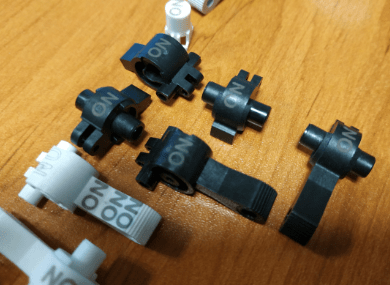

Examples

Sivart Green Laser Marking Machine

At Sivart, we have more than 15 years of experience in the industrial marking market in all kinds of laser, micro-percussion or scratch technology. Contact us without obligation to resolve any questions about this industrial marking system, our team will be happy to help you in your project.