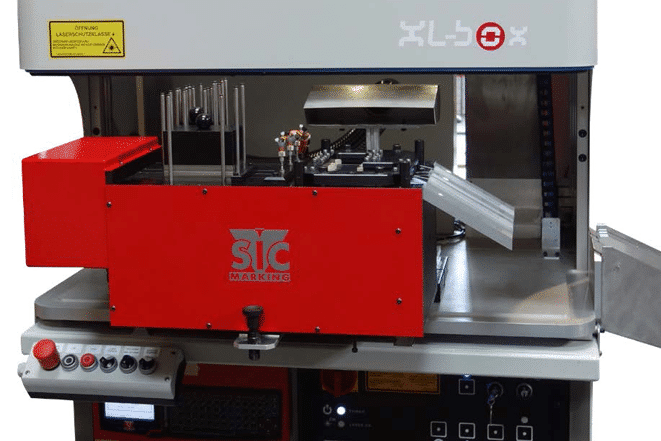

case study

Laser Marking Hydraulic Valves

The main advantages of laser marking hydraulic valves include:

Durability: Laser markings are permanent and resistant to harsh environments, including high temperatures, pressure, and exposure to chemicals, ensuring long-lasting legibility even in demanding industrial conditions.

Precision and Accuracy: Laser marking offers high precision, allowing for detailed markings such as serial numbers, logos, and barcodes, which are crucial for tracking and quality control.

No Consumables: Unlike traditional methods, laser marking doesn’t require inks, labels, or other consumables, making it a cost-effective and eco-friendly solution.

Customisation: Laser technology provides flexibility, allowing for customizable markings that can include various fonts, graphics, and complex patterns tailored to specific needs.

Improved Traceability: Laser markings enhance the traceability of hydraulic valves, supporting inventory management, maintenance tracking, and regulatory compliance.

Faster Production: The speed and efficiency of laser marking reduce overall production time, contributing to quicker turnaround and increased manufacturing efficiency.

Overall, laser marking improves the functionality, traceability, and sustainability of hydraulic valves while reducing costs and enhancing product quality.