cases of application

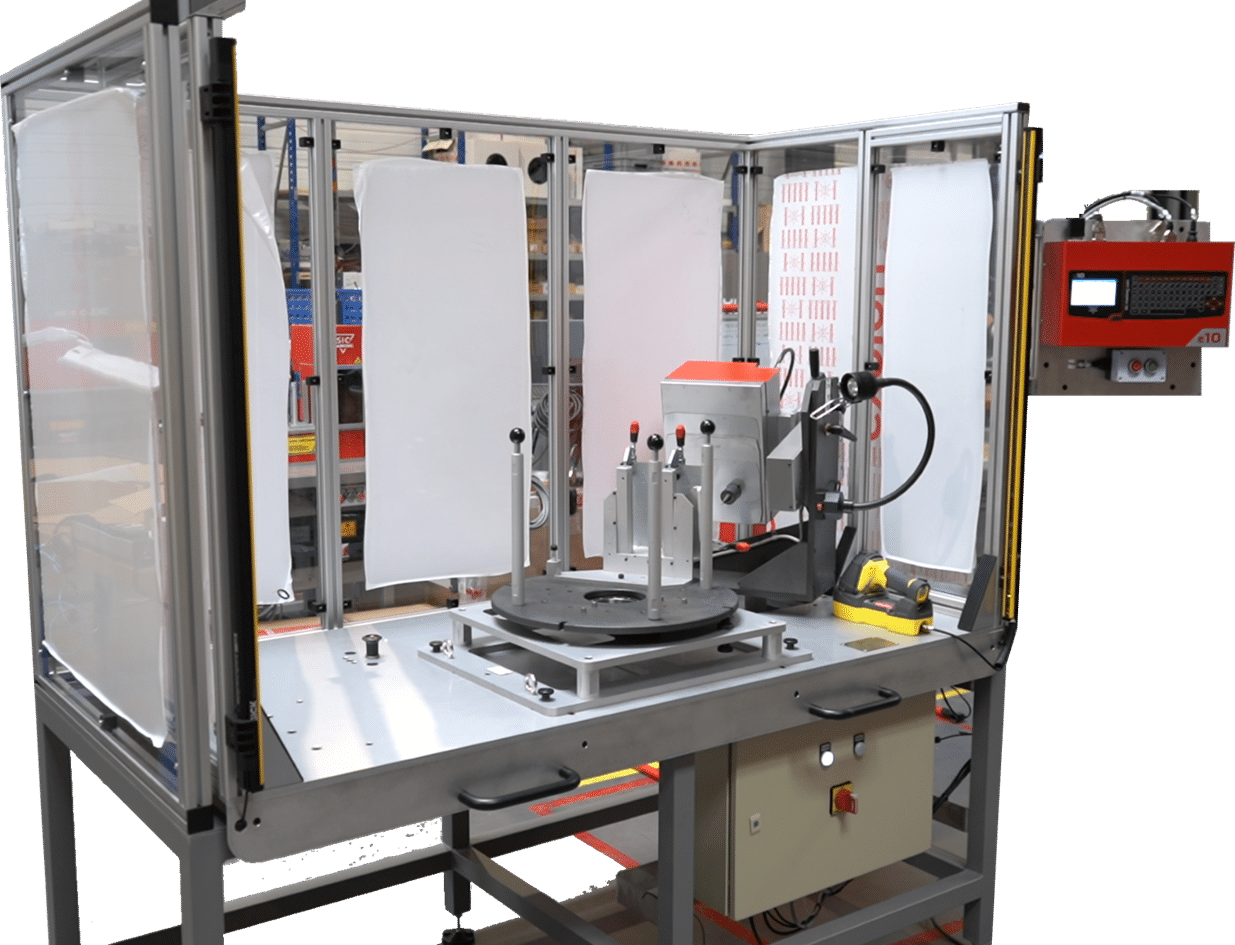

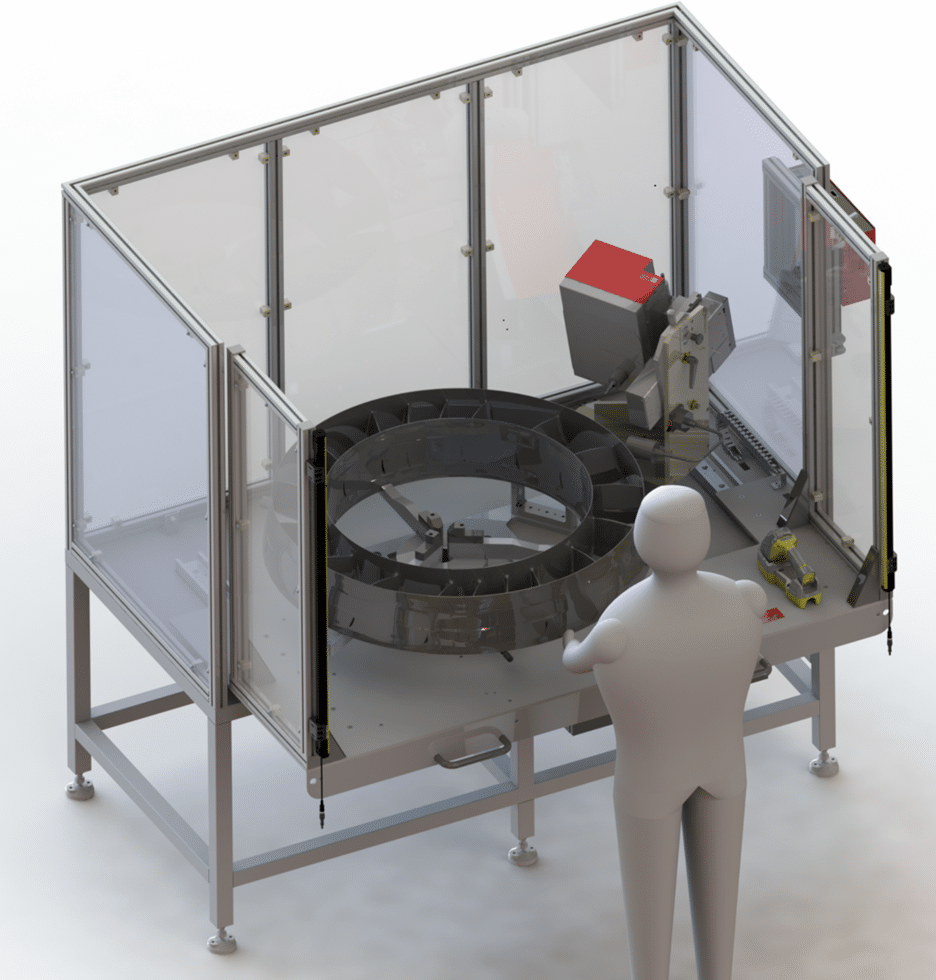

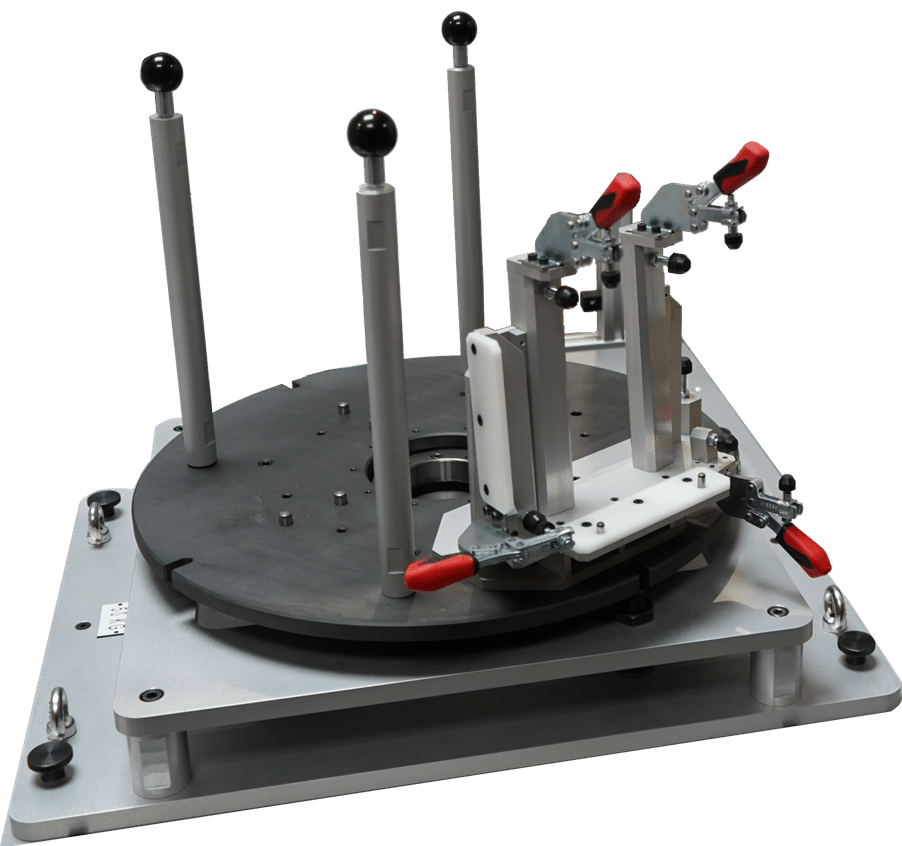

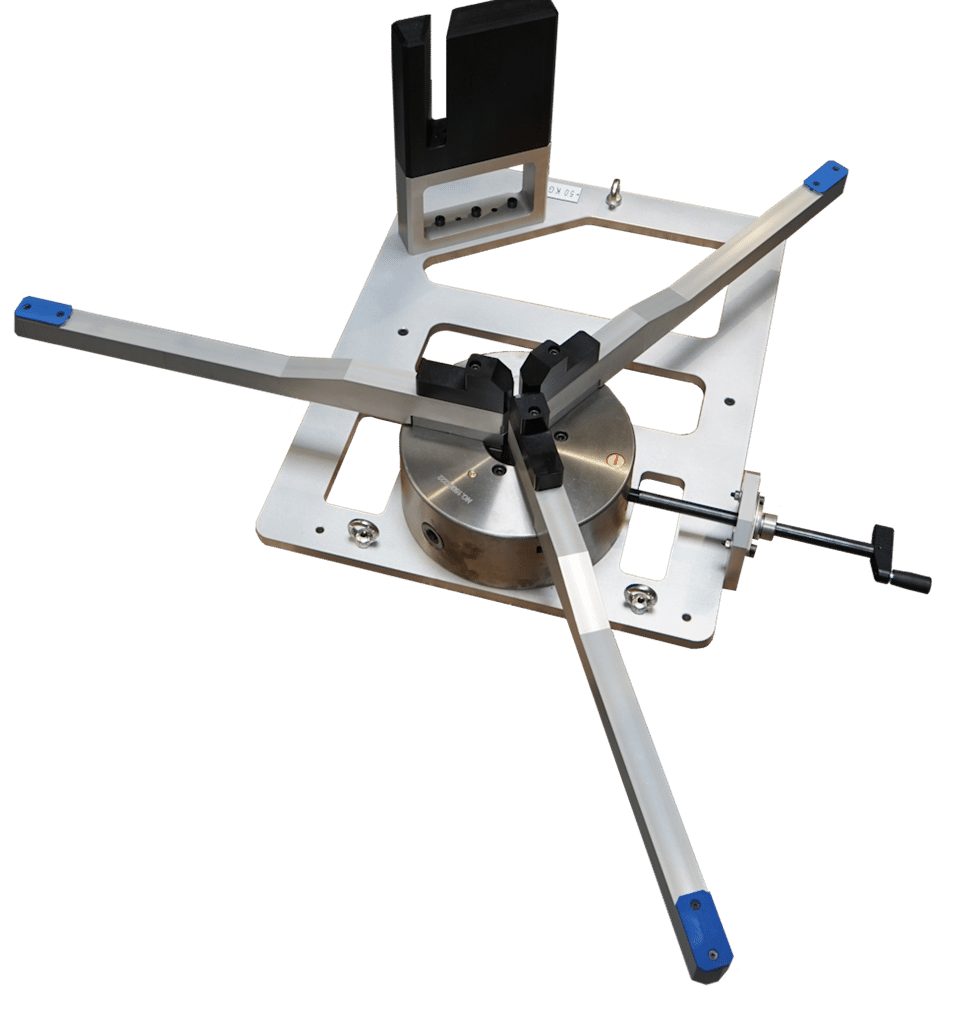

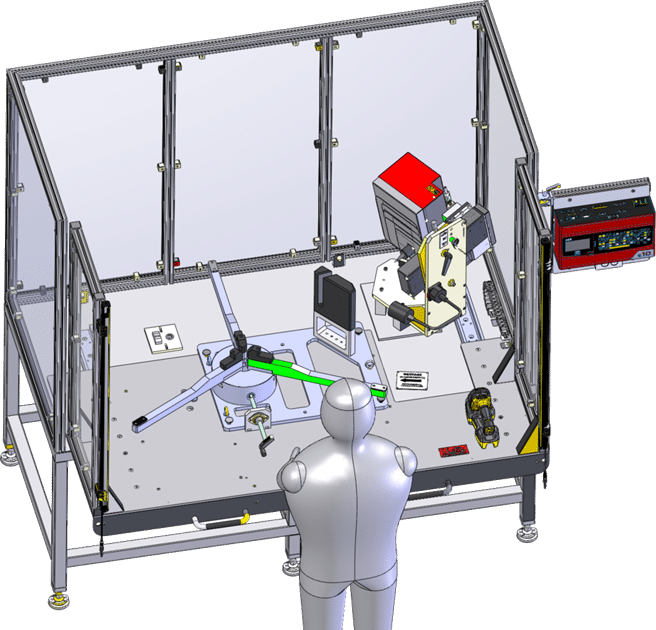

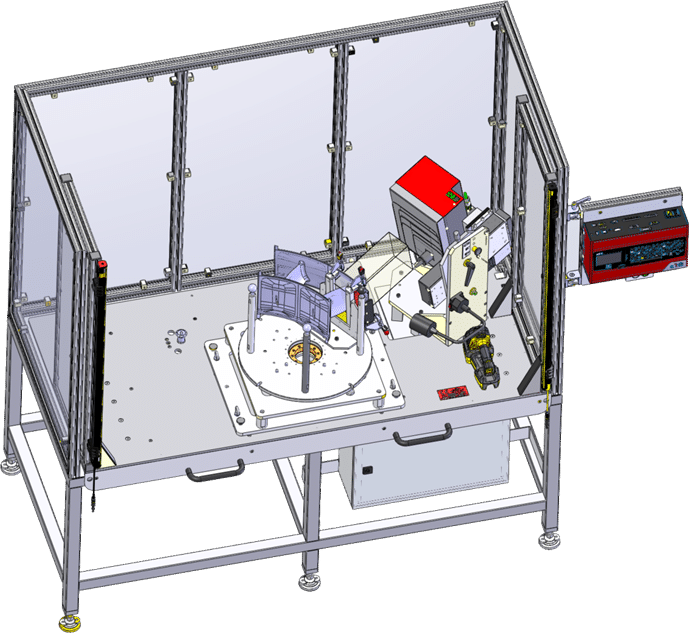

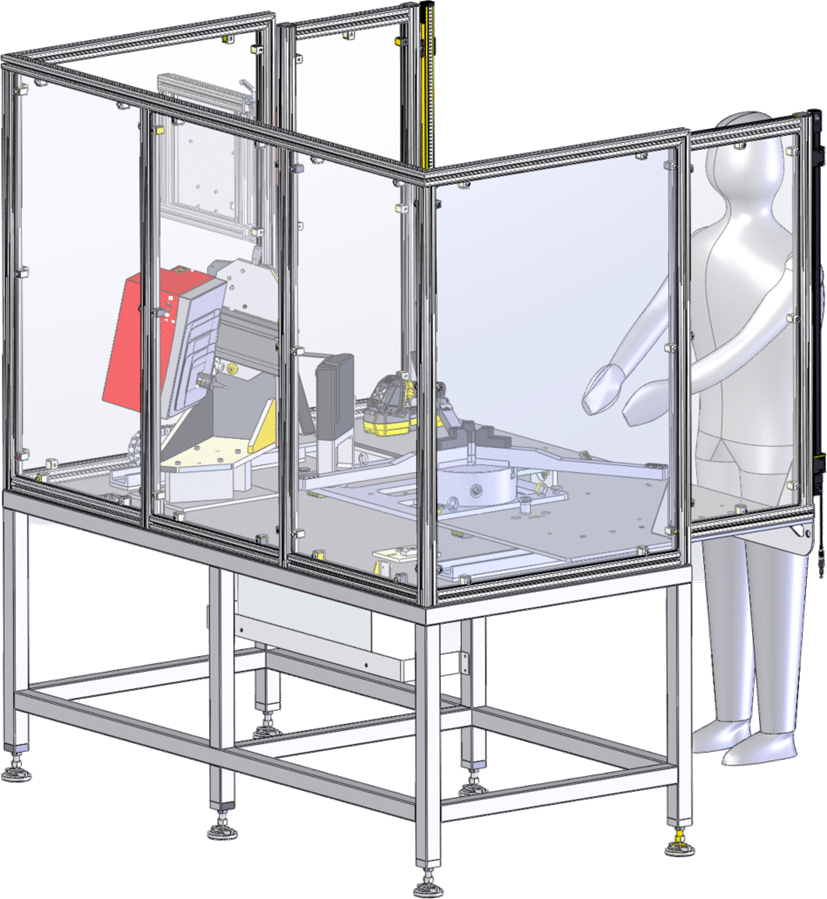

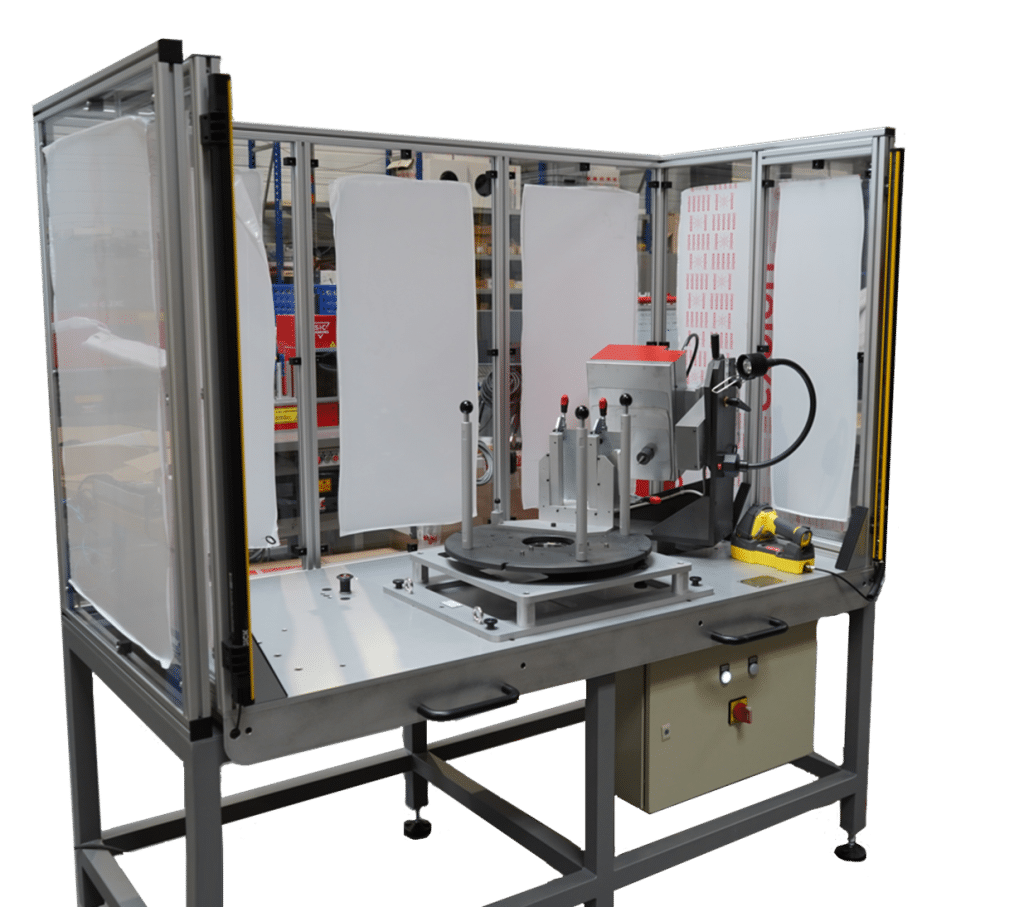

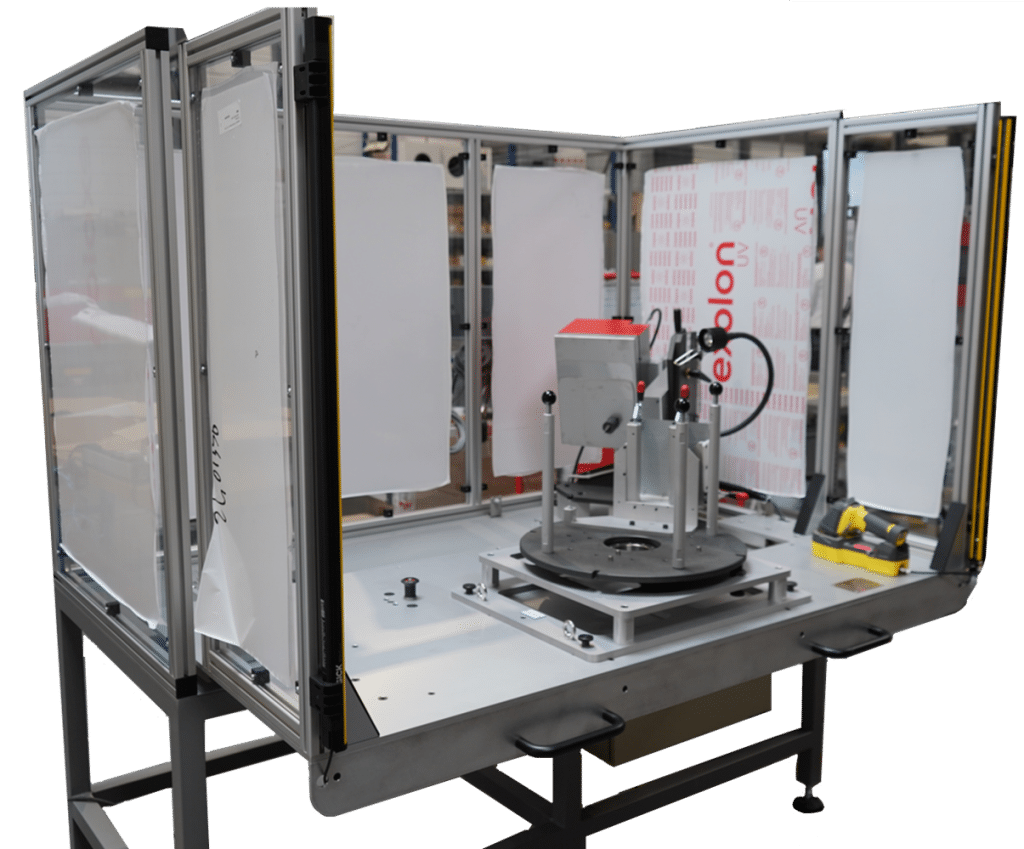

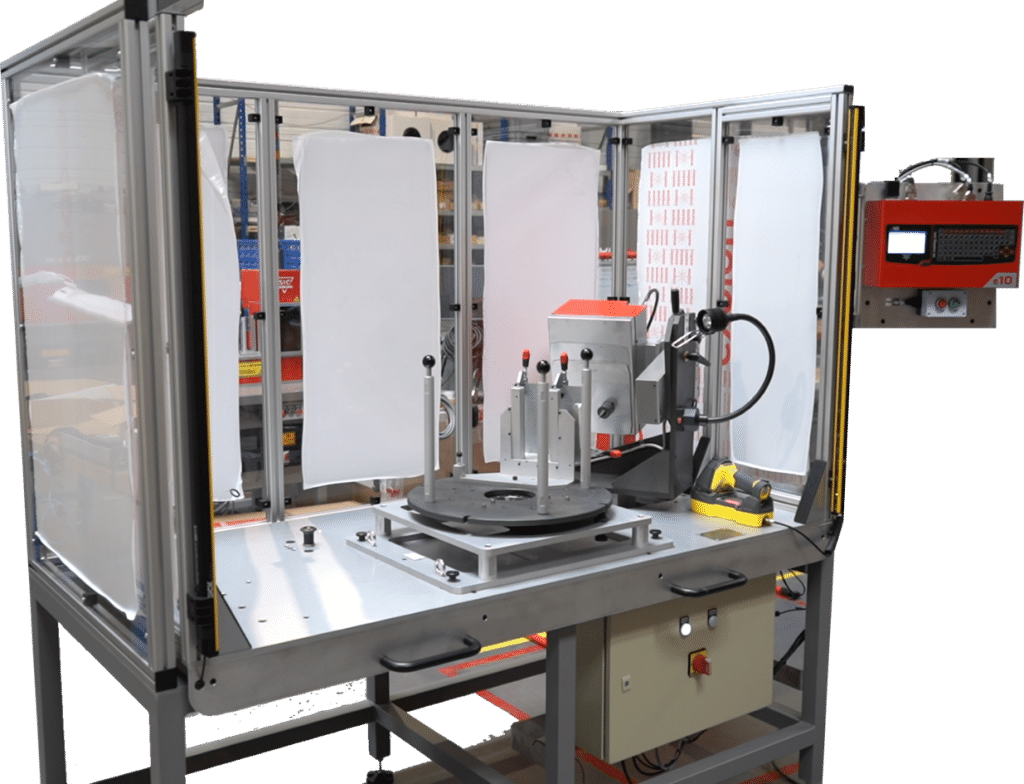

How to guarantee marking in compliance with aeronautical standard DT05-89, while respecting space constraints and flexibility for parts of varying sizes?

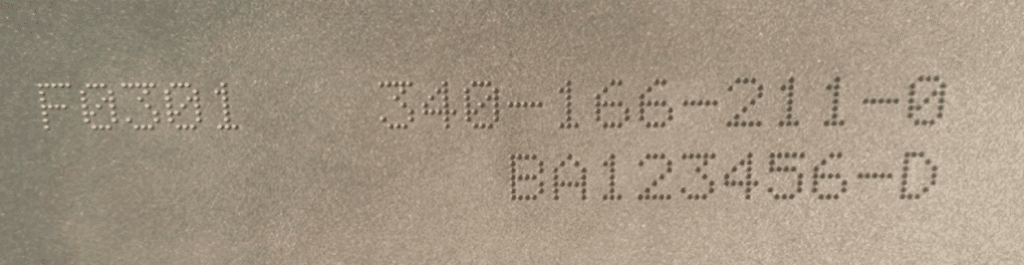

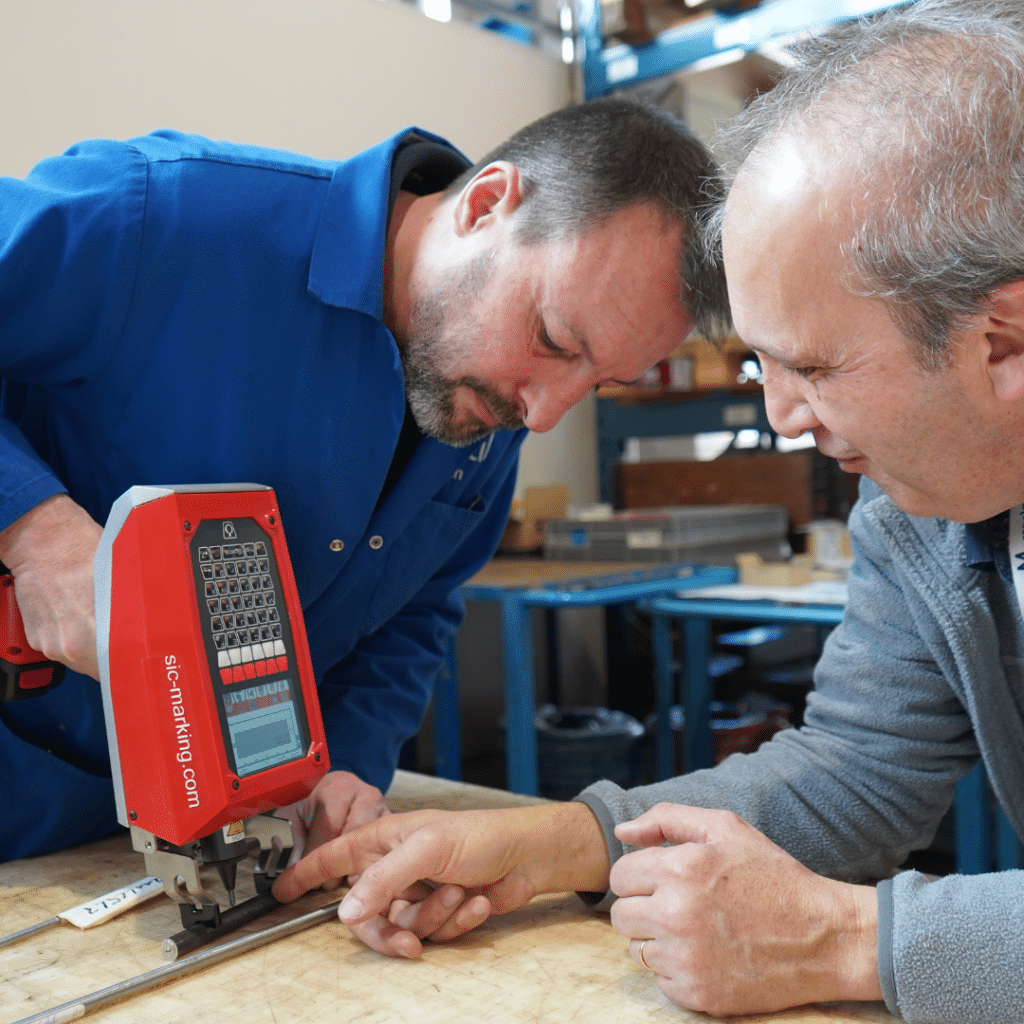

In the aerospace industry, almost all components must be marked, and the marking of critical parts must meet strict standards. Our customer, a subcontractor to an aeronautical equipment manufacturer, needed a high-quality marking solution that complied with the industry’s specific requirements, in particular standard DT05-89.

This well-known subcontractor, specializing in the manufacture of aircraft engines, asked us to design a manual marking station for parts classified as “N2”, failure of which could have serious consequences for the engines.