Advances in laser marking for electronic components: miniaturization and accuracy

By 2024, significant transformations are expected in the field of laser marking, particularly in the electronic components industry. This industry, known for its precision and efficiency, is in continuous evolution and it is necessary to keep up with its new needs in order to be able to put laser marking at its service.

A few weeks ago we talked about the importance of identification and traceability of electronic components in the industry. Today we look at the demands of miniaturization and precision that define the current era of advanced electronics and how laser marking can participate in its evolution.

What is miniaturization?

Miniaturization is the technological process of trying to reduce the size of electronic devices and components. It has become a dominant trend in the electronics industry, where components and parts are becoming smaller and smaller, resulting in smaller products.

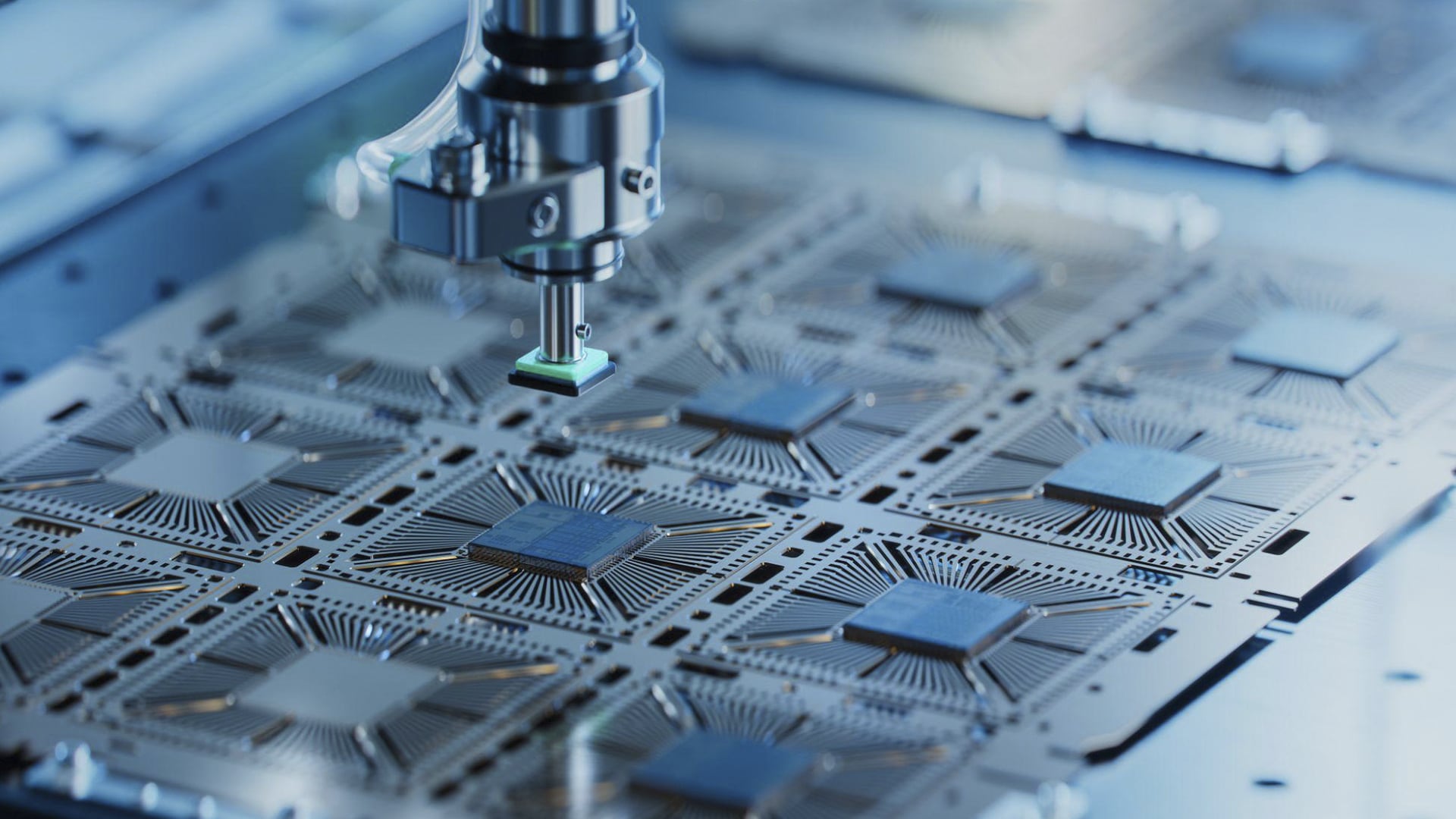

Electronic miniaturization represents one of the greatest challenges and advances within the technology industry, as it enables the creation of ever smaller, more efficient devices with expanded capabilities. In this context, laser marking emerges as an indispensable tool, offering unmatched precision and flexibility for the manufacture of micro-scale electronic components.

With this trend, marking methods must be increasingly precise and must be able to work with millimeter accuracy on microscopic scales. Laser marking, with its ability to produce fine, detailed marks, has become an indispensable tool in this process.

Laser marking, indispensable

Thanks to its ability to make extremely fine engravings without physical contact, laser marking ensures the structural integrity of components, avoiding damage and deformation that more invasive methods could cause. In addition, this technology enables the creation of high-precision electrical traces and connections in small spaces, which is essential for the design and operation of miniaturized devices. It has become an indispensable tool, as it is capable of etching vital information into components as small as microchips or printed circuit boards, without affecting their functionality or structural integrity.

In addition to being an ideal tool for this type of product, laser marking responds to the growing demand for product customization and traceability.

Security and traceability in electronics

In a world where security and authenticity of electronic components are of paramount importance, laser marking offers an effective solution. It allows the incorporation of unique codes, serial numbers or QR codes directly on electronic components, facilitating traceability and inventory management. This feature is especially crucial in sectors such as aerospace, defense and automotive, where accuracy and reliability are essential.

But laser marking has expanded beyond mere product identification. The implementation of laser marking in the security and traceability of electronic miniatures goes beyond facilitating identification and inventory management, becoming a fundamental pillar in combating piracy and ensuring product authenticity. This technology enables the creation of indelibly precise and durable marks that are virtually impossible to replicate without the proper equipment and technical expertise, providing a significant barrier against counterfeiting.

In addition, the ability to invisibly integrate detailed information on the origin, date of manufacture and supply chain into each component, without affecting its dimensions or performance, strengthens quality and safety control mechanisms throughout the production and distribution chain. Thus, laser marking not only ensures compliance with international regulations, but also provides companies with advanced tools to protect their intellectual property and strengthen consumer confidence in their products, critical aspects for success in the highly competitive global electronics market.

It is important to remember that standardization and compliance with international regulations in the laser marking of electronic components is becoming increasingly stringent. Companies are looking to comply with global standards to ensure that their products are accepted in international markets, which requires a precise and uniform approach to the marking process.

Advances in laser marking

To delve deeper into the advances of laser marking in electronic miniaturization, it is important to consider innovations in precision and adaptability. Technological advances have enabled the development of laser marking machines that offer micrometer precision, essential for small electronic components. These machines use state-of-the-art laser technology, capable of adjusting laser intensity and focus to avoid heat damage, ensuring the integrity of electronic components.

The implementation of advanced software and intelligent control systems allows complete customization and automation of the marking process, ensuring high repeatability and consistent quality in the marking of electronic components, regardless of their size or material.

The development of new laser sources, including diode and solid-state lasers, represents a significant advance in laser marking technology. These innovations enable greater energy efficiency, improved marking quality and the ability to work with a wide range of materials. These technologies pave the way for broader and more specialized applications, offering customized solutions that meet the specific needs of the electronics industry.

We are at a turning point in laser marking technology for electronic components. Miniaturization, precision, safety and traceability, as well as integration with advanced technologies are the key trends that define this era. As the technology continues to evolve, we can expect to see increased adoption in various industrial applications, further cementing its position as an essential tool.

At SIC Marking we continue to innovate and develop technology that improves and refines the most complex laser marking processes. For any questions, or if you want to receive more information, contact with us See you in future articles!