Advances in laser encoders for various applications

Technological evolution has driven the development of laser coders, transforming industries with their accuracy, efficiency and versatility. In this article we will discuss the latest advances in laser technology, including UV, CO2, fiber laser and green laser systems.

These developments not only expand coding and marking capabilities, but also open up new possibilities for applications in various industries. We explain more.

UV laser technology

UV laser technology stands out for its ability to mark at low temperatures, making it ideal for heat-sensitive applications. Its accuracy and marking quality make it the preferred choice for marking extremely small codes on delicate materials such as plastics, glass and coatings.

In the pharmaceutical and cosmetics industry , UV laser technology has established itself as an optimal solution for product marking, thanks to its ability to make precise and detailed engravings on sensitive materials without generating heat damage. This precision is essential for complying with strict regulations, ensuring traceability and making counterfeiting more difficult. In addition, energy efficiency and rapid adaptability to different packaging make UV laser technology a sustainable and versatile option.

CO2 Laser Encoders

CO2 laser coders are known for their flexibility and efficiency in marking a wide range of materials, from paper and cardboard to glass and plastic. Their ability to make high quality engravings without physical contact makes them ideal for the packaging, food and beverage industries. where hygiene and speed are essential.

They stand out for their versatility and thanks to their improved energy efficiency and minimal maintenance requirements they reduce operating costs, making them a profitable investment. The speed of marking and ease of integration into automated systems optimize production processes, while the absence of consumables makes them a safe and sustainable option.

Fiber laser

Fiber laser coders are noted for their durability, energy efficiency and ability to produce high-quality permanent marks on a wide variety of materials, including metals and engineering plastics. This technology is ideal for industries such as automotive, electronics and manufacturing, where precision and resistance to extreme conditions are required.

Their long service life and low maintenance make them economical in the long term, while their energy efficiency contributes to sustainable business practices. Fiber laser coders, with their versatility and precision, are an advanced marking solution that improves product traceability and optimizes production processes, aligning perfectly with the efficiency and quality demands of today’s industries.

Green laser

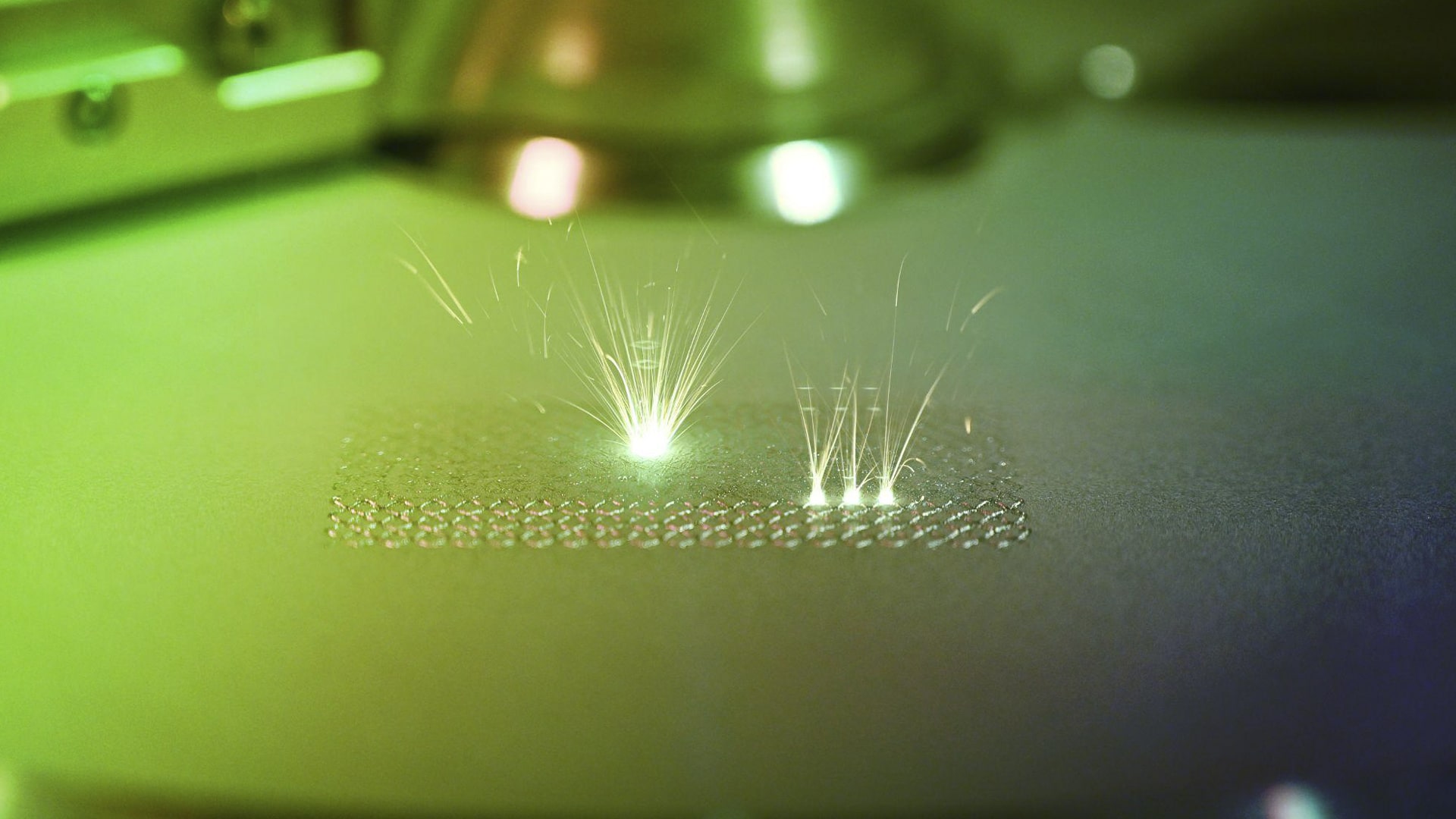

The green laser has established itself as the ideal solution for materials that are challenging for other types of lasers. It stands out for its ability to accurately mark sensitive and reflective materials, such as certain plastics and precious metals, without damaging them. This technology is especially valued in industries such as electronics, jewelry and medical device manufacturing. where precision and material care are critical.

Green laser coders offer high quality, high resolution marks, ideal for applications that demand fine detail and minimal thermal stress. With its versatility and efficiency, the green laser presents itself as an advanced solution for overcoming marking challenges on traditionally difficult materials, ensuring integrity and value in the final product.

Industry Impact

These advances are transforming the industry by offering significant improvements in efficiency, quality and sustainability. These technologies increase production speed and reduce errors through their accuracy and ability to integrate into automated processes. Permanent, legible marking improves product traceability and regulatory compliance, vital for consumer safety and supply chain efficiency.

In addition, by eliminating the need for consumables such as inks and solvents, they help reduce waste and energy consumption, aligning with greener production practices. The customization and design capabilities offered by these laser technologies open up new possibilities for customized products, satisfying consumer demand for personalization without increasing production costs.

At SIC Marking, we continue to explore and embrace these technological advances to offer our customers state-of-the-art laser coding solutions that meet their unique needs.Visit our website for more information, we’ll be happy to advise you!